Amorphous &

Nickel-Iron

In keeping with MH&W International’s commitment to providing industry-leading magnetic solutions, we have partnered with a premier OEM supplier to expand our portfolio with high-performance Amorphous and 80% Nickel-Iron alloy (Permalloy) cores. Available in various configurations—including toroids, gapped toroids, cut cores, and specialty stampings—these materials allow MH&W to offer highly competitive pricing for both low-frequency and high-frequency magnetic designs. This strategic expansion ensures that our customers receive the most efficient, high-quality solutions for their specific engineering requirements across the entire frequency spectrum.

MH&W International’s Amorphous Cut Cores are designed for high-performance power applications, offering a combination of high saturation magnetic induction and low core loss. These cores exhibit exceptional temperature stability across a broad operating range of -55°C to 130°C, making them ideal for demanding environments. Engineered for versatility, they are primarily utilized in output choke coils for SMPS, DC/DC converters, PFC choke coils, and uninterruptible power systems.

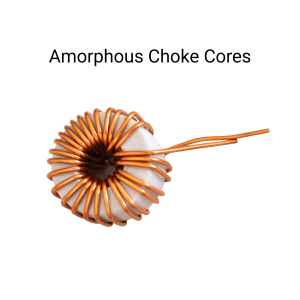

MH&W International’s Amorphous Choke Cores are engineered for superior efficiency, featuring high saturation magnetic induction and significantly lower core loss compared to conventional materials. These cores provide excellent DC bias characteristics and low leakage flux while offering a compact, lightweight design that saves valuable board space. Designed for high-frequency performance, they maintain stable characteristics up to 300kHz across a wide range of operational temperatures.

MH&W International’s Amorphous Cores with Air Gap are engineered for precision energy storage, featuring large DC bias characteristics and a permeability range of 180 to 200. These cores offer low core loss and exhibit consistent frequency and temperature performance, ensuring reliability in high-efficiency power conversion. The integrated air gap design allows for superior magnetic control in critical applications, ranging from PFC chokes for UPS and PDP TV sets to inverter circuits.

MH&W DC Current Immunity Composite Cores are advanced magnetic components engineered specifically for high-precision energy measurement. By combining amorphous and nanocrystalline materials, these cores achieve a unique “composite” performance that provides robust DC current immunity, preventing magnetic saturation even in the presence of significant DC components.

Permalloy Nickel-Iron Cores are high-performance magnetic solutions designed for applications requiring extreme accuracy and efficiency. These cores are characterized by low coercivity and low remanence, which ensure minimal energy loss and rapid response during magnetic switching. With high linearity and precision, they are ideally suited for sensitive roles such as PFC choke coils and output chokes coils for SMPS.

In keeping with MH&W International’s commitment to providing industry-leading magnetic solutions, we have partnered with a premier OEM supplier to expand our portfolio with high-performance 80% Nickel-Iron alloy (Permalloy) cores. These cores feature low coercivity and low remanence, ensuring minimal energy loss and rapid magnetic switching. Engineered for high linearity and precision, they are ideal for sensitive applications such as PFC choke coils, SMPS output chokes, and DC/DC converters.

Contact our engineers for technical support on high-precision Permalloy solutions, request an RFQ for custom configurations like specialty stampings, or browse our inventory for high-efficiency choke coils and transformers.