Keramold®

Injection Molding Compound

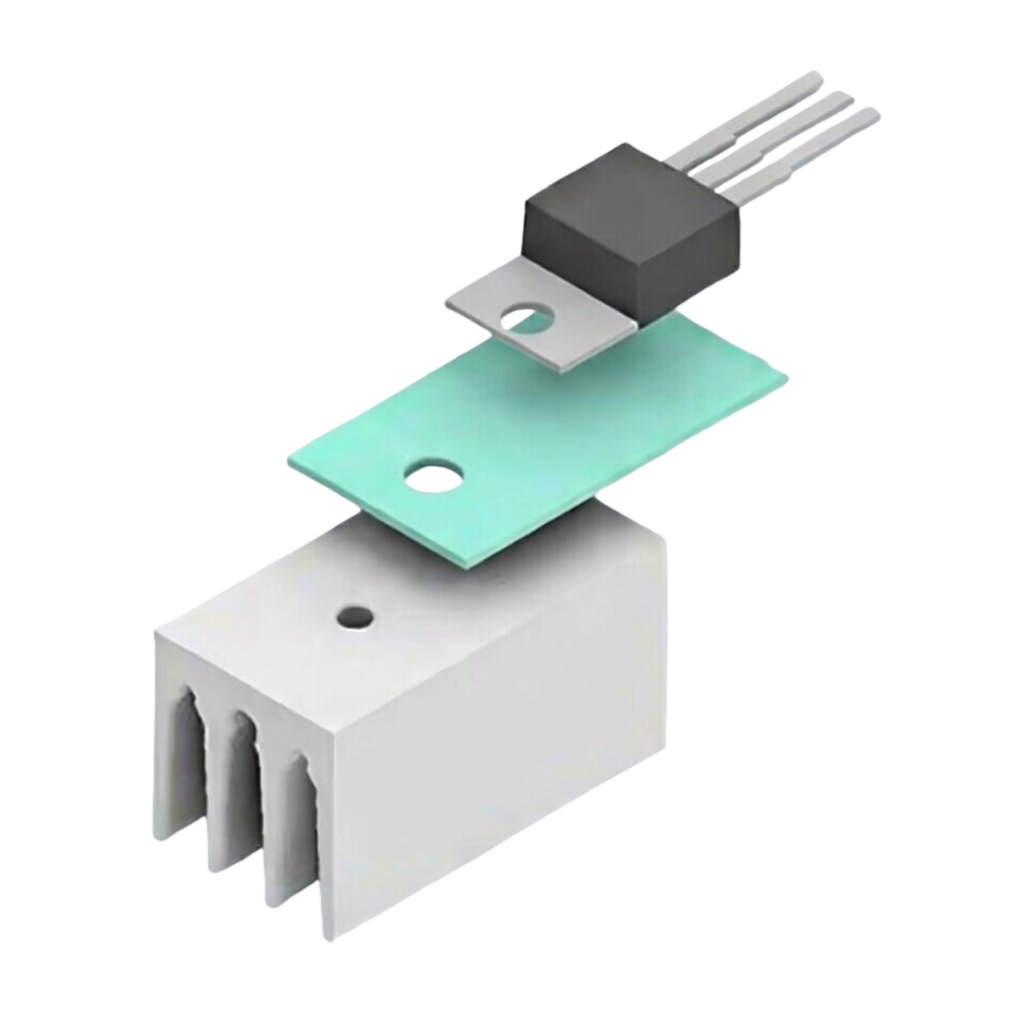

As miniaturization and high performance increase thermal loads on electronic assemblies, reliable heat dissipation is essential to prevent failure. To maximize component longevity, Kerafol® offers the Keratherm® range of standard films, providing high-performance interface solutions with excellent electrical insulation. These specialized films deliver an uncomplicated, cost-effective method for conducting heat to sinks in demanding technical environments.

Exceptional Electrical Insulation

The standardard films provide high dielectric strength, ensuring that electronic components remain electrically isolated while heat is being transferred, preventing short circuits.

High Thermal Conductivity

These films are engineered with specialized ceramic fillers to maximize heat dissipation, significantly lowering component operating temperatures.

Mechanical Stability & Durability

Unlike thermal greases, these films do not pump out, dry out, or migrate over time, ensuring long-term reliability and consistent performance throughout the device’s lifespan.

Ease of Handling & Application

Available as self-adhesive or non-adhesive sheets and die-cut parts, they are much cleaner and faster to install than liquid alternatives, reducing assembly time and costs.

Excellent Surface Compliance

The materials are designed to be flexible and soft enough to compensate for microscopic surface irregularities, minimizing thermal contact resistance between surfaces.

Customizable Solutions

Why should i use a standard film?

Pre-Cured Consistency: Standard films are solid, pre-formed sheets. This guarantees a uniform thickness across the entire interface and prevents “pump-out”—where liquid TIMs migrate out of the gap during heat cycles.

Mechanical Durability: Unlike pastes that can dry out or crack, films are resilient. They act as a vibration dampener and maintain structural integrity under mechanical shock, making them ideal for automotive or industrial hardware.

Electrical Isolation: Most films offer high dielectric strength. They transfer heat efficiently while acting as an electrical insulator, preventing short circuits on high-density boards or high-voltage components.

Manufacturing Efficiency: Films are “clean” and die-cuttable. They can be shaped to exact component dimensions and applied quickly like a sticker, which simplifies mass assembly and makes rework much cleaner than scraping off grease.

Who is Kerafol®?

Standard Film Comparison Chart

| Film | Thermal Conductivity (W/mK) | Thermal Resistance (K/W) | Breakdown Voltage (kV) | Measured Thickness (mm) | Hardness (Shore A) | Possible Thicknesses (mm) | Characteristics | Datasheet | View Product |

|---|---|---|---|---|---|---|---|---|---|

| 86/82 | 6.5 | 0.090 | 1.0 | 0.250 | 60-70 | 0.250 - 0.275 | High Thermal Conductivity | VIEW | |

| U90 | 6.0 | 0.082 | 4.0 | 0.200 | 70-85 | 0.100 - 0.300 | Silicone Free. High Thermal Conductivity. | VIEW | |

| 86/60 | 4.5 | 0.140 | 5.0 | 0.250 | 45-60 | 0.250 - 0.325 | High Thermal Conductivity | VIEW | |

| 86/50 | 3.5 | 0.160 | 1.5 | 0.225 | 70-80 | 0.125 - 0.300 | Adhesive and Fiberglass Options | VIEW | |

| U85 | 3.0 | 0.165 | 6.0 | 0.200 | 70-85 | 0.200 - 0.225 | Silicone Free. Excellent Thermal Properties. | VIEW | |

| 86/30 | 2.5 | 0.220 | 1.5 | 0.225 | 70-80 | 0.125 - 0.500 | Good Thermal Conductivity & Isolation | VIEW | |

| U80 | 1.8 | 0.200 | 4.0 | 0.150 | 80-90 | 0.150 - 0.175 | Silicone Free. Cost Effective Solution | VIEW | |

| 86/37 | 1.8 | 0.320 | 8.0 | 2.25 | 65-75 | 0.225 - 0.300 | High Isolation. Self Adhesion | VIEW | |

| 70/50 | 1.4 | 0.440 | 5.0 | 2.50 | 80-90 | 0.250 - 0.275 | Good Price Performance Ratio. | VIEW |

Frequently Asked Questions

What are the primary benefits of using Keratherm® Standard Films?

These films provide high thermal conductivity and excellent electrical insulation in a single, thin layer. They are also highly durable, as they do not dry out or lose effectiveness over long periods of continuous use.

How do these films handle surface irregularities on components?

The smooth, flexible surface of the films allows them to conform to microscopic irregularities between the heat source and the sink. This ensures that no air is trapped in the interface, which significantly improves overall heat dissipation.

Are there options available for easier installation or mechanical stability?

Yes, the films can be reinforced with fiberglass for added mechanical strength and stability during assembly. Additionally, they are available with an optional single-sided adhesive coating to assist with positioning and “up-side down” attachment.

What temperature ranges can Keratherm® films withstand?

In what formats are these thermal films supplied?

As thermal demands rise with miniaturization, MH&W’s Thermal Division provides the expertise and Keratherm® materials necessary to prevent system failure. Contact our engineers for technical support, request an RFQ, or purchase standard sheets directly from our online shop.