Magnetec

CoolBlue® & NaLa®

Permanent Bearing Protection

Electrical Solution

CoolBLUE® and NaLa® offer a targeted electrical solution for bearing and EMI related issues, thus ensuring optimal performance and longevity, unlike less effective “band-aid” approaches such as grounding rings or brushes.

Easy Installation

CoolBLUE® and NaLa® offer a faster and more efficient integration into motor systems compared to conventional methods. This simplified design minimizes downtime during installation and reduces the need for complex modifications, making them a practical choice for both new and retrofit applications.

Ruduce Downtime

By effectively filtering out high-frequency currents, CoolBLUE® and NaLa® chokes significantly reduce the risk of electrical fluting and EMI issues such as ghost shutdowns, leading to decreased downtime and a more reliable system operation.

Extend Motor Life

By mitigating harmful high-frequency currents, CoolBLUE® and NaLa® chokes protect motor bearings from electrical damage like pitting, frosting, and fluting, thus extending the motor lifespan and reducing the need for constant bearing replacements.

Protect Nearby Electronics

CoolBLUE® and NaLa® chokes effectively reduce conducted electromagnetic interference (EMI) from variable frequency drives (VFDs). They do this by absorbing high-frequency EMI currents, preventing them from traveling through power cables and interfering with nearby electronic equipment.

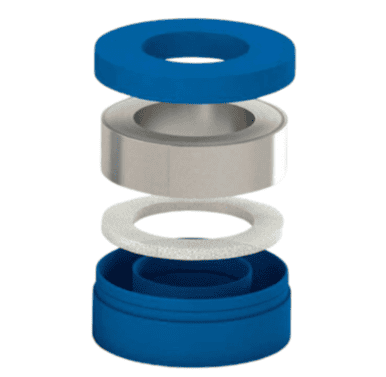

Nanocrystalline Technology

Base Material: The core is primarily composed of iron (Fe), which provides the foundation for its magnetic properties and contributes to its high saturation flux density, allowing it to handle strong magnetic fields.

Key Additives: Specific elements like silicon (Si), niobium (Nb), copper (Cu), and boron (B) are added in precise proportions. These additions play crucial roles in refining the microstructure and enhancing the material’s soft magnetic characteristics.

Microstructure: This microstructure is achieved through a specialized manufacturing process involving rapid solidification and controlled heat treatment, resulting in superior magnetic performance.

Resulting Properties: The nanocrystalline structure yields desirable magnetic properties: high permeability for efficient flux conduction, low coercivity for minimal energy loss, low core losses for improved efficiency, and high saturation flux density for handling high power.

Watch the CoolBlue® Video

Discover how CoolBLUE® Inductive Absorbers, featuring nanocrystalline cores, can significantly reduce or even eliminate motor bearing damage in variable frequency drive (VFD) applications. Watch this video for a detailed explanation.

CoolBlue® Kit Selection Tool

Frequently Asked Questions

How long do CoolBLUE® & NaLa® chokes last?

CoolBLUE® and NaLa® chokes offer a permanent, maintenance-free solution to electrical problems. Their magnetic cores are designed to last a lifetime, unlike traditional grounding rings or brushes which is a mechanical “band-aid” solution that wears out.

Can I just use CoolBLUE® and not NaLa®?

Why is my shaft voltage not decreasing after CoolBLUE® and NaLa® installation?

CoolBLUE® and NaLa® chokes mitigate damaging high-frequency currents by reducing the current component of the waveform. A Rogowski coil and oscilloscope are required for accurate high-frequency current measurement. The voltage measured at the shaft is NOT causing the damage to your system, the current is!

Where should I install the CoolBLUE® and NaLa®?

CoolBLUE® and NaLa® chokes should ideally be installed as close as possible to the variable frequency drive (VFD). For installations with size constraints, please contact the MH&W engineering team.

Do I have to test to ensure the CoolBLUE® and NaLa® are working properly?

Our CoolBLUE® and NaLa® selection tool is sufficient for approximately 95% of applications. However, testing is required to verify proper operation and confirm that high-frequency currents are being reduced to safe levels.

MH&W’s Sales and Engineering teams provide specialized technical support for CoolBLUE® and NaLa® nanocrystalline cores, which are engineered to eliminate damaging high-frequency motor bearing currents in VFD applications.