Kerafol®

Softtherm® Gap Filler Pads

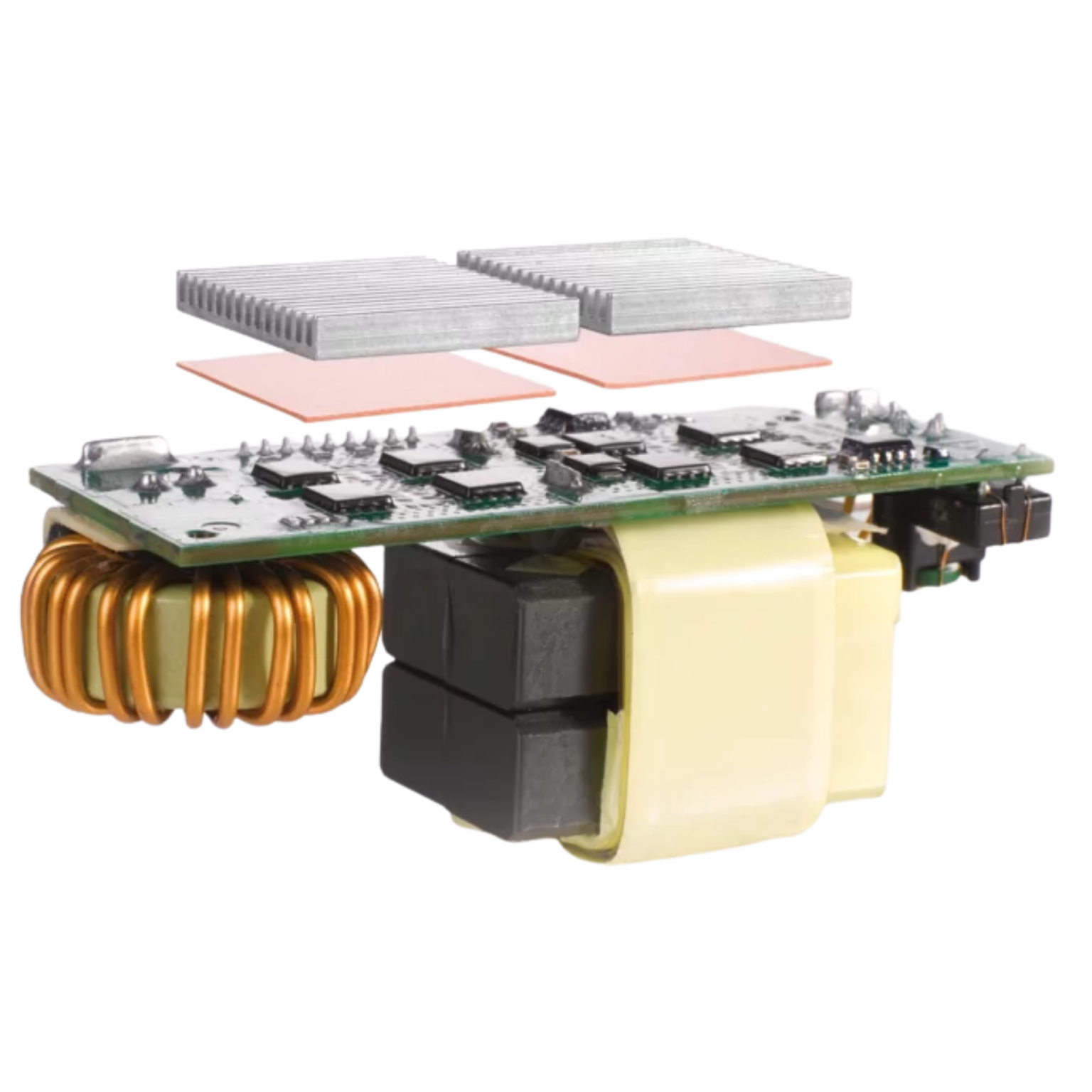

As the push for higher power densities and smaller device footprints creates significant air gaps between components and heat sinks, robust thermal management is critical to maintain system stability. To bridge these varying distances, Kerafol® offers the Softtherm® range of gap filler pads, providing ultra-soft and highly compressible interface solutions that effectively displace air in large cavities. These specialized pads deliver a versatile, low-stress method for conducting heat in complex assemblies where standard thin films cannot reach or conform to irregular surface geometries.

Bridging Large Vertical Gaps

Multi-Height Components

A single large gap filler pad can cover an entire PCB section, cooling multiple components of varying heights simultaneously. This greatly simplifies assembly compared to applying individual thin films to every component.

Long-Term Interface Stability

Unlike thermal greases or lower-end materials that can dry out, “pump out,” or crack over time, Keratherm gap pads are fully cross-linked elastomers. They maintain their elastic “memory” and consistent thermal performance over years of continuous use in harsh environments.

Elimination of Secondary Adhesives

High Dielectric Protection

Because these pads are significantly thicker than standard films, they provide a much more robust electrical insulation barrier. This makes them ideal for high-voltage applications where a thin film might be susceptible to “cut-through” from sharp component edges or PCB burrs.

Ease of Rework & Maintenance

Unlike permanent thermal glues or messy pastes, gap filler pads allow for clean and easy removal. If a board requires testing or a component needs replacing, the pad can be removed without leaving significant residue, ensuring a fast and non-destructive rework process.

Why should i use Gap Filler Pads?

Superior Conformability: Unlike thinner standard films, gap filler pads are soft and highly compressible, allowing them to mold into irregular surface topographies and fill large air gaps between components of varying heights.

Stress Reduction: The low-modulus nature of these pads applies minimal pressure to sensitive components during assembly, preventing mechanical stress or board bowing while maintaining excellent thermal contact.

Tolerance Compensation: These pads are ideal for applications with high mechanical tolerances, as they can compress significantly to take up space where a standard film would leave a performance-robbing air pocket.

Vibration Dampening: Due to their thicker, more compliant structure, gap filler pads provide enhanced vibration and shock absorption, protecting delicate solder joints and internal connections in rugged industrial or automotive environments.

Who is Kerafol®?

Softtherm® Comparison Chart

| Film | Thermal Conductivity (W/mK) | Thermal Resistance (K/W) | Breakdown Voltage (kV) | Measured Thickness (mm) | Hardness (Shore 00) | Possible Thicknesses (mm) | Characteristics | Datasheet | View Product |

|---|---|---|---|---|---|---|---|---|---|

| 86/200 | 1.0 | 1.20 | 8.0 | 0.5 | 10-20 | 0.5 - 5.0 | Super Soft Material. Double Layer with Good Insulation. | VIEW | |

| 86/125 | 1.5 | 0.80 | 6.0 | 0.5 | 10-25 | 0.5 - 5.0 | Fiberglass Reinforcement. Extra Soft Material.. | VIEW | |

| 86/225 | 2.0 | 0.60 | 6.0 | 0.5 | 30-45 | 0.5 - 5.0 | Fiberglass up to 4.0mm. Soft Material. Good Insulation. | VIEW | |

| 86/228 | 2.0 | 0.60 | 6.0 | 0.5 | 30-45 | 0.5 - 3.0 | Soft Double Layer Material with Good Insulation. | VIEW | |

| 86/235 | 2.0 | 0.60 | 6.0 | 0.5 | 25-40 | 0.5 - 5.0 | Low Bleeding. Fiberglass up to 2.0mm. Good Insulation. | VIEW | |

| 86/238 | 2.0 | 0.60 | 6.0 | 0.5 | 25-40 | 0.5 - 3.0 | Soft Double Layer Pad with Low Bleeding & Good Insulation. | VIEW | |

| U110 | 2.0 | 1.20 | 8.0 | 0.5 | 60-75 | 0.5 - 3.0 | Silicone Free. Elastic with Good Aging Behavior & Low Hardness. | VIEW | |

| 86/320 | 2.5 | 0.50 | 5.0 | 0.5 | 25-38 | 1.0 - 5.0 | Soft Material with Fiberglass up to 1.5mm. High Elastic Properties. | VIEW | |

| 86/325 | 3.0 | 0.41 | 6.0 | 0.5 | 35-50 | 0.5 - 4.0 | Soft Material. Good Properties. Fiberglass up to 1.0mm. | VIEW | |

| 3500 | 3.5 | 0.36 | 5.0 | 0.5 | 45-65 | 0.5 - 4.0 | Soft Material with Good Elastic Behavior. and Properties.. | VIEW | |

| 86/450 | 4.5 | 0.27 | 5.0 | 0.5 | 65-75 | 0.5 - 4.0 | Great Price Performance Single Layer, No Fiberglass. | VIEW | |

| 86/525 | 5.5 | 0.44 | 1.25 | 0.5 | 50-65 | 0.5 - 3.0 | Adhesive Available. No Fiberglass. Single Layer.. | VIEW | |

| 6000 | 6.0 | 0.41 | 4.0 | 0.5 | 55-75 | 0.8 - 3.0 | Excellent Thermal Properties. Elastic and Low Hardness.. | VIEW |

Frequently Asked Questions

How much should I compress a Softtherm® pad for optimal performance?

At maximum pressure, pads should not be compressed beyond 30% of their original thickness. Exceeding this limit may cause the material to “leak out” or apply excessive mechanical stress to components.

What thickness range is available for these Softtherm® Gap Filler Pads?

Do these pads require a separate adhesive for mounting?

Can the pads be reused or repositioned during assembly?

Yes, depending on the surface and the specific material, these pads can often be repositioned during assembly. Their fully cross-linked elastomeric structure allows for cleaner removal than pastes or glues, though reuse should be verified by a design engineer.